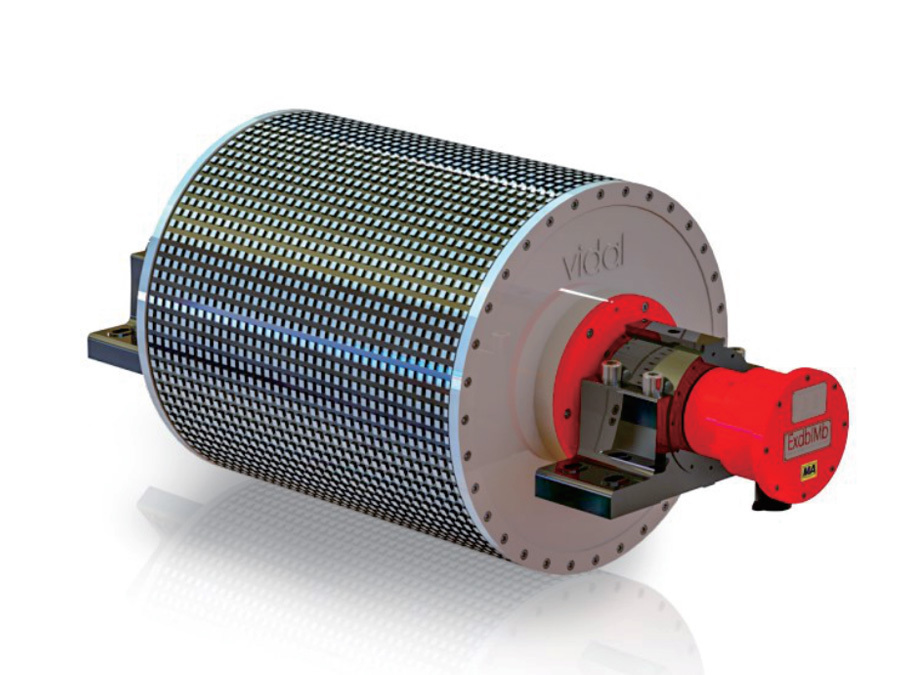

Vidal Transmission Drives the Future

Driven by technological innovation, continuously exploring cutting-edge technologies in the industry.

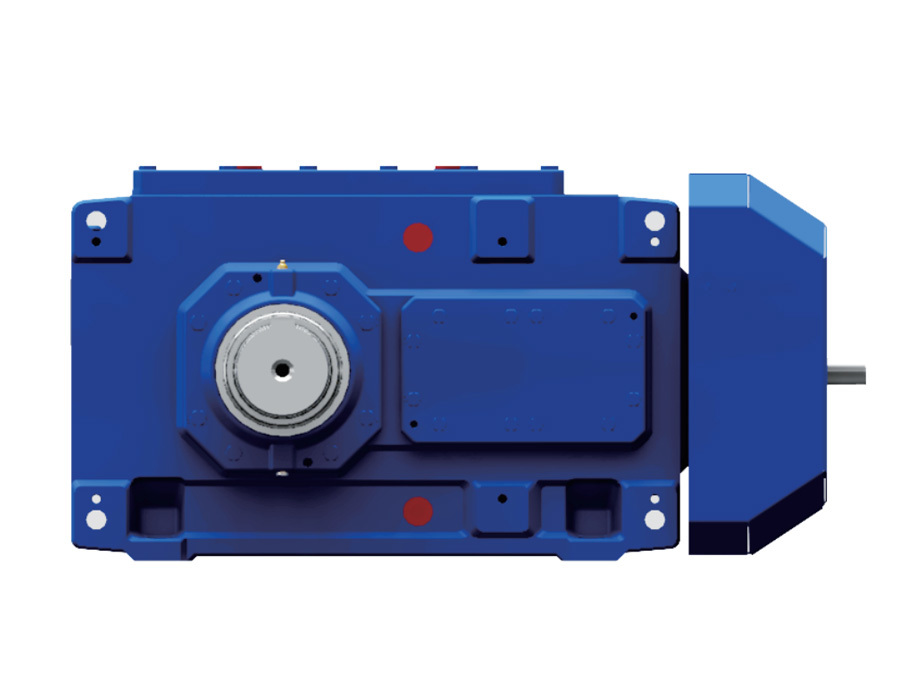

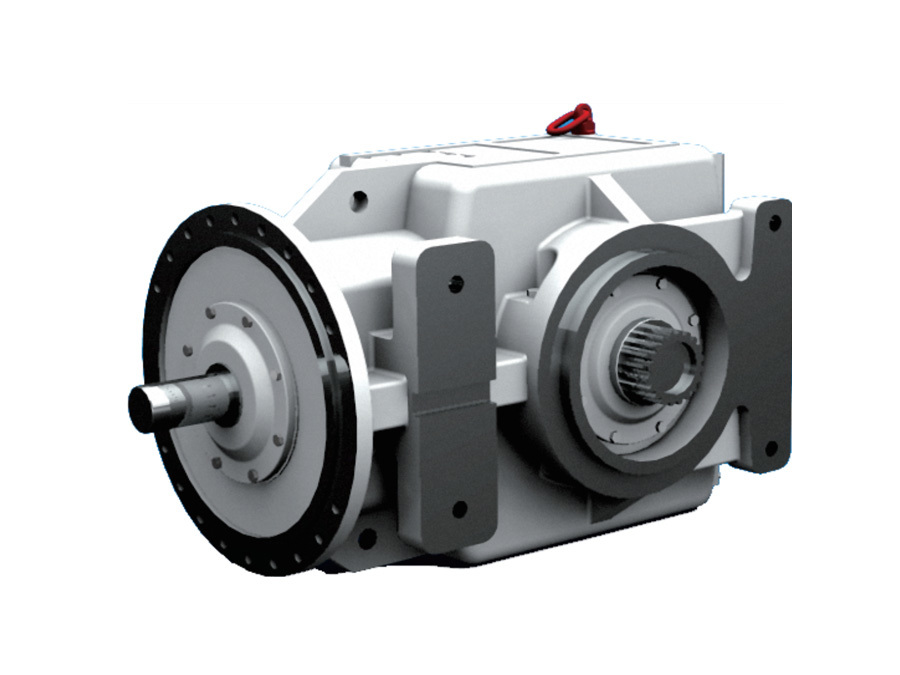

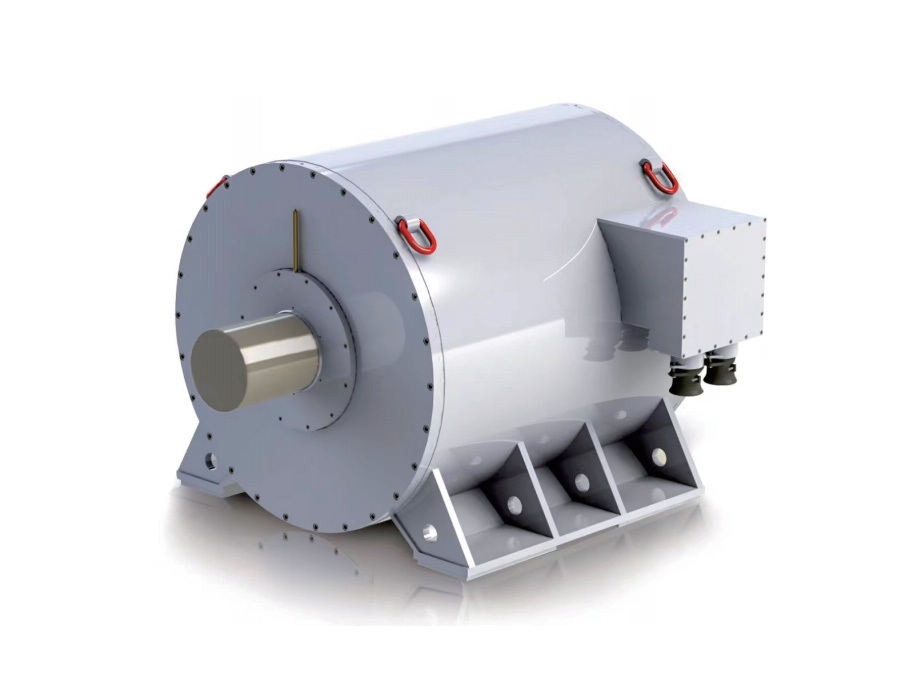

Provide safe, reliable, and energy-efficient permanent magnet motor intelligent drive systems and mechanical transmission products for various industries in society.

READ MORE